The Challenge

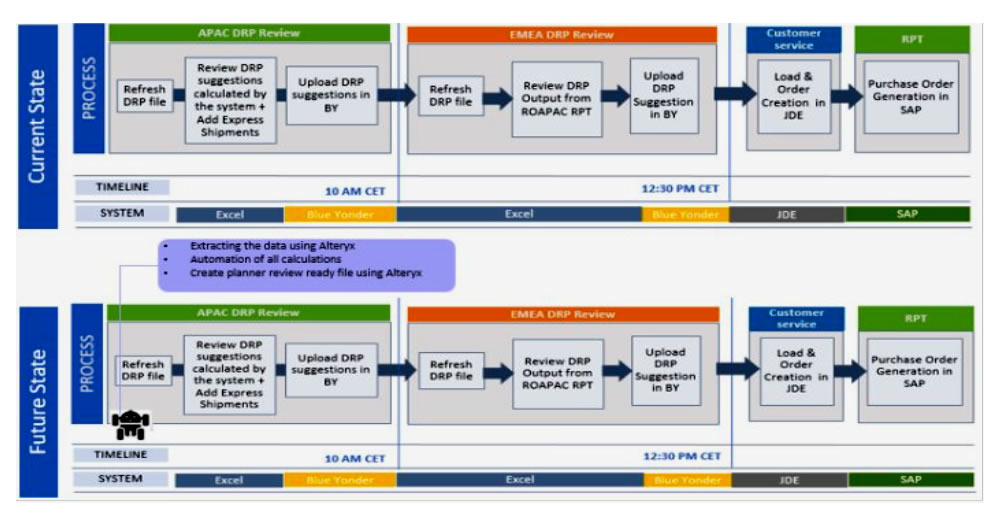

The Distribution Requirements Planning (DRP) process in the healthcare domain was heavily manual, requiring planners to refresh data from multiple systems, adjust parameters, and manage inputs daily. This manual effort made the process time-consuming, error-prone, and inconsistent across regions. With multiple planning teams managing operations for different regions, ensuring accuracy and timeliness became increasingly complex.

solution

To address these challenges, the project team designed and implemented an automated DRP solution that integrated data from key systems such as OMP, CDL, JDE, and SAP.

- System Integration: Alteryx workflows were built to connect the various platforms, creating a closed-loop system

- Automated Data Refresh & Processing: Manual data entry and refresh activities were replaced with automated workflows that ensured up-to-date information was always available.

- Parameter Optimization : Advanced logic was implemented to calculate and adjust key planning parameters such as safety stock, lead time, and committed quantities, ensuring more reliable planning outcomes.

- Comprehensive Input Handling: The solution integrated multiple inputs

- including inventory, forecasts, demand, open purchase orders, and material master parameters into a unified model.

- Franchise Coverage: The automation was scaled across multiple franchises within the portfolio, ensuring consistency across diverse product lines.

This automation transformed the DRP process from a manual, resource-intensive workflow into a streamlined, scalable, and data-driven system, enabling planners to focus on decision-making rather than routine data handling.

Scope of the Project

The goal was to optimize and automate the DRP process by creating a seamless data flow across critical systems and minimizing manual interventions. The scope covered multiple product franchises and spanned across 13 regions in the Asia-Pacific market.

Business Impact

- Significant Efficiency Gains: Reduced manual interventions saved approximately 1,800 hours annually, freeing up planners to focus on strategic decision-making.

- Improved Accuracy: Automated data integration eliminated errors, leading to more reliable supply and demand planning.

- Scalability Across Regions: The solution was successfully applied across multiple regions and product franchises, ensuring standardization.

- Risk Reduction: By minimizing dependency on manual processes, the likelihood of delays and failures in the supply chain was reduced.

- Enhanced Responsiveness: Enabled faster adjustments to demand changes, improving product availability across markets.

Technology Environment

- Alteryx – for data integration and workflow automation

- SAP / JDE / OMP / CDL – core enterprise systems for planning and execution

- Custom Automation Workflows – for data refresh, parameter updates, and reporting