The Challenge

The manufacturing company faced multiple operational challenges:

- Limited real-time visibility into equipment and production performance, causing delays in issue detection.

- Fragmented data sources across MES, ERP, and SCADA, making reporting inconsistent and analysis difficult.

- Reactive maintenance practices, leading to unplanned downtime, higher costs, and reduced equipment reliability.

- Quality control inefficiencies, with defects identified only after production completion and reliance on error-prone manual inspection.

Executive Summary

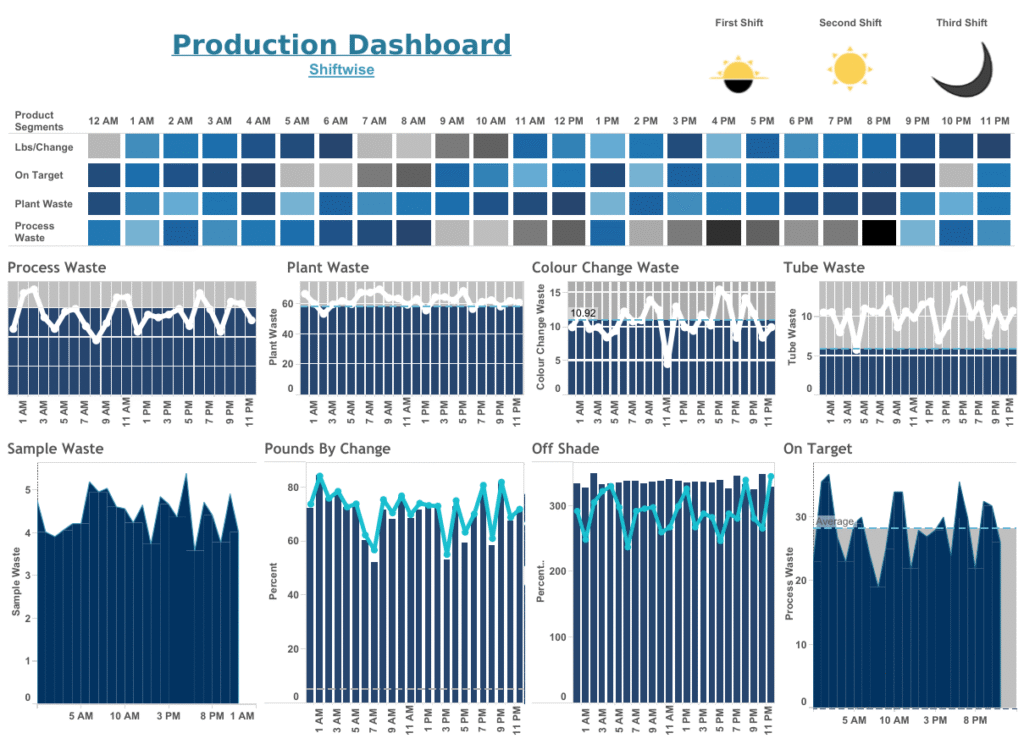

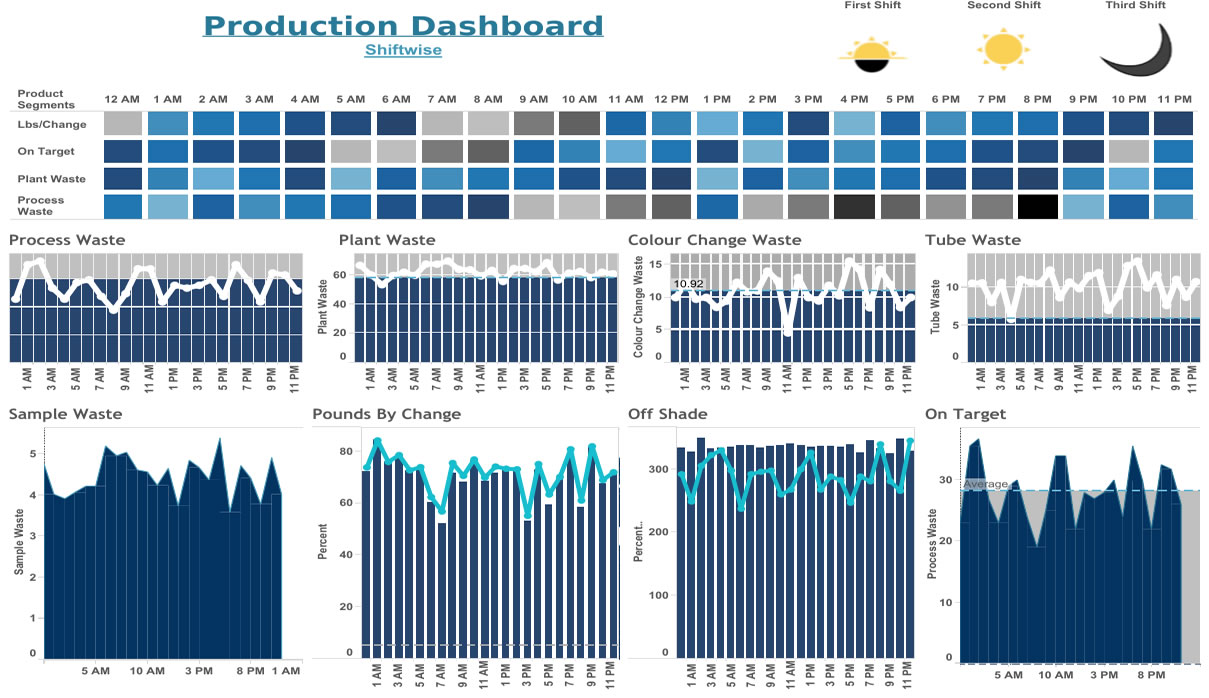

A mid-sized manufacturing company implemented a comprehensive Tableau-based production analytics dashboard solution to transform their operational visibility and decision-making capabilities. The initiative addressed critical challenges in production monitoring, equipment utilization tracking, and quality control processes, resulting in significant improvements in Overall Equipment Effectiveness (OEE), reduced downtime, and enhanced operational efficiency across multiple production lines.

solution

The company implemented a multi-layered Tableau dashboard ecosystem that included:

- Real-Time Production Monitoring Dashboard → OEE calculations, machine status, shift performance.

- Maintenance Analytics Dashboard → Predictive maintenance indicators, MTBF tracking, and cost analysis.

- Quality Control Dashboard → Defect rate monitoring, root cause analysis, compliance checks.

- Production Planning Dashboard → Capacity utilization, bottleneck identification, and schedule adherence.

Scope of the Project

The initiative focused on building a centralized Tableau-based production analytics dashboard to:

- Enable real-time visibility into production lines.

- Integrate data from multiple sources (MES, ERP, SCADA, and quality systems).

- Shift maintenance from reactive to predictive.

- Improve quality monitoring, production planning, and decision-making.

- Provide accessibility for operators, supervisors, and management across devices.

Business Impact

The solution delivered measurable business impact:

Production Efficiency

- 22% increase in Overall Equipment Effectiveness (OEE).

- 35% reduction in unplanned downtime.

- 18% improvement in throughput due to bottleneck detection.

- 45% faster issue response time.

Quality Improvements

- 30% reduction in defect rates.

- 25% fewer customer complaints.

- 40% improvement in first-pass yield.

- 50% faster quality inspection through automation.

Maintenance Optimization

- 28% cost reduction in maintenance.

- 40% higher MTBF for critical equipment.

- 35% leaner spare parts inventory.

Cost & Strategic Benefits

- 15% lower production costs.

- 20% reduced energy consumption per unit produced.

- Strengthened compliance with quality and industry standards.

- Transition from reactive to data-driven culture.

Technology Environment

- Visualization & Analytics: Tableau (core dashboard platform).

- Data Sources: MES, ERP, SCADA, Quality Systems.

- Data Integration: ETL pipelines for real-time feeds.

- Database: SQL-based storage for structured production and quality data.