Challanges

The organization faced multiple supply chain inefficiencies impacting business performance. Frequent stockouts of fast-moving products led to lost sales opportunities, while overstocking of slow-moving items increased holding costs and waste. Supplier delays often disrupted timely deliveries, and inefficient logistics drove up shipping costs. Additionally, high defect rates from quality control lapses posed risks to brand reputation. These issues were worsened by fragmented data systems and reliance on manual processes, limiting visibility into inventory levels, supplier performance, and shipping operations.

Scope of Project

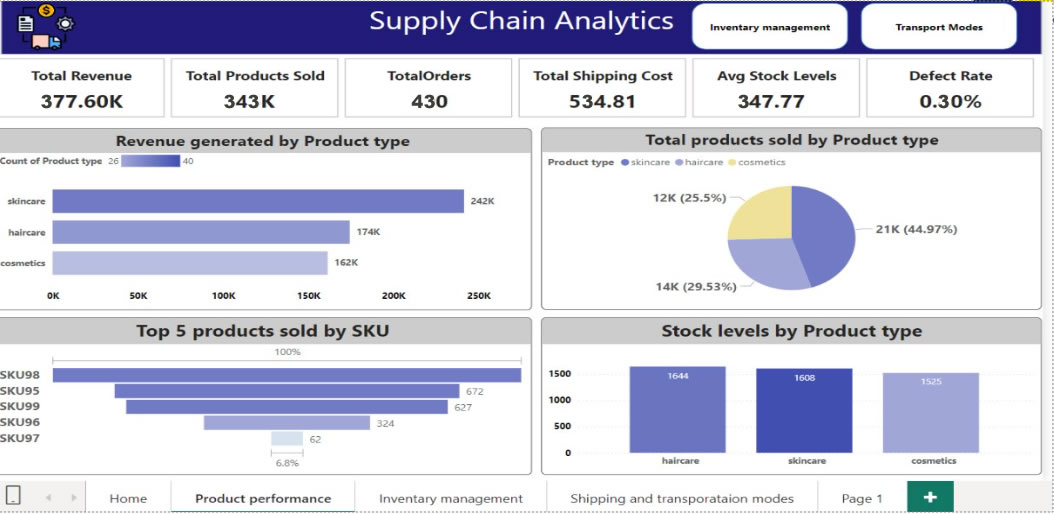

The project focused on analyzing supply chain data for haircare and skincare products to improve operational efficiency. Key goals included monitoring inventory levels, tracking supplier reliability, optimizing logistics costs, and improving product quality control. By leveraging data-driven insights, the organization sought to ensure optimal stock levels, reduce supply chain bottlenecks, and enhance customer satisfaction.

Scope of Project

The solution was built around a data-driven supply chain optimization model with advanced dashboards and analytics.

- Inventory Optimization: Automated alerts were implemented for both low stock levels and excess inventory, ensuring timely replenishment and avoiding unnecessary overstocking.

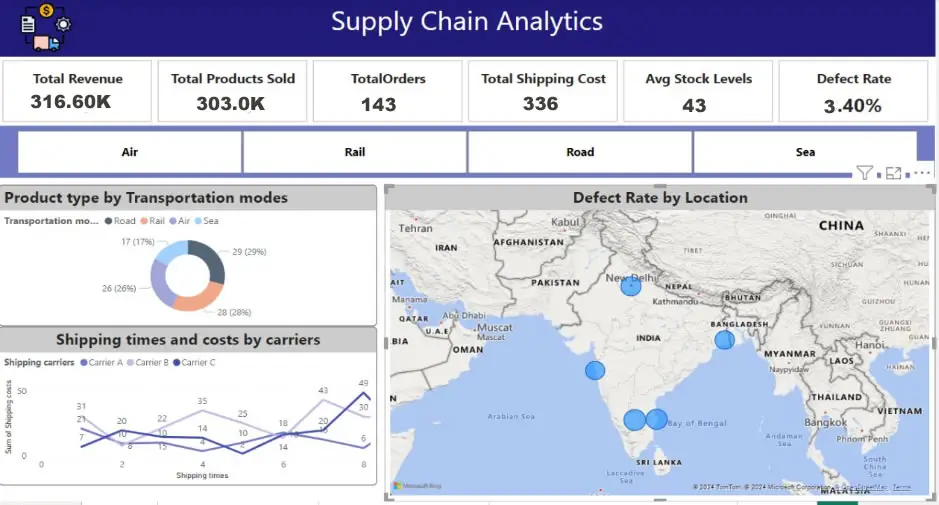

- Supplier Performance Management: Dashboards tracked supplier lead times and order fulfillment rates, enabling the identification of reliable partners and quick action against underperforming suppliers.

- Logistics & Shipping Efficiency: Analytics were used to monitor shipping costs and optimize delivery routes. Real-time tracking of delivery times helped reduce delays and improve on-time fulfillment.

- Quality Control Monitoring: Dashboards monitored defect rates and inspection results, allowing the business to identify recurring issues and reduce returns.

- Predictive Insights: Sales trends and demand forecasting models provided better planning capability, helping to align production with actual consumer demand.

By integrating these solutions into a unified system, the organization shifted from reactive management to a proactive supply chain strategy.

Business Impact

The implementation delivered measurable improvements across the supply chain:

- Reduced Stockouts and Excess Inventory, improving product availability while lowering carrying costs.

- Improved Supplier Relationships through data-backed performance evaluations and stronger delivery reliability.

- Optimized Logistics Costs by reducing shipping inefficiencies and minimizing delays.

- Enhanced Product Quality with better defect tracking, leading to fewer returns and stronger brand reputation.

- Greater Customer Satisfaction driven by reliable product availability and faster, more efficient delivery.

Overall, the project enabled the company to achieve higher operational efficiency, reduce costs, and strengthen its competitive position in the consumer beauty products market.

Technology stack

- Data Integration & Preparation: SQL, Excel

- Visualization & Dashboards: Power BI / Tableau

- Data Analytics & Forecasting: Statistical models for demand forecasting and supplier performance analysis

- Automation: Alerts and notifications for inventory and supplier KPIs